#Simatic step 7 manager update#

The CPU then sends signals to update the status of the outputs. The CPU evaluates the statuses of the inputs, outputs, and other variables as it executes a stored program. The primary function of a PLC’s input circuitry is to convert the signals provided by these various switches and sensors into logic signals that can be used by the CPU.

These analog signals represent machine or process conditions as a range of voltage or current values. Other modules or inputs respond to analog signals. Some input modules or points respond to digital inputs, also called discrete inputs, which are either on or off. The type of the input modules or points used by a PLC depends upon the types of the input devices used. The basic elements of a PLC include input modules or points, a central processing unit (CPU), output modules or points, and a programming device. While the specific applications vary widely, all PLCs monitor inputs and other variable values, make decisions based on a stored program, and control outputs to automate a process or machine.

#Simatic step 7 manager software#

PLCs differ from office computers in the types of tasks that they perform, and the hardware and software they require to perform these tasks. If one of the time stamps is not current, then this could indicate an issue with that device or the connection of that device.A programmable logic controller (PLC), also referred to as a programmable controller, is the name given to a type of computer commonly used in commercial and industrial control applications.

#Simatic step 7 manager Pc#

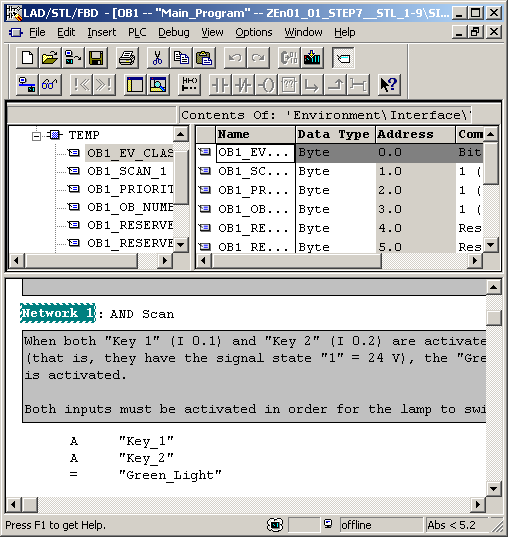

Save the hardware configuration which only saves into the local windows PC project files.Īs a diagnostic check, a successful connection will show a current time stamp status on all devices as shown below on the web page “Manage My Remote” on the website. Original settings are shown restored below. Now we are done with our monitoring, so we go back to the Hardware configuration screen and open the Ethernet module to reset its properties back to their original state.Ĭhange these IP addresses back to the original settings. The status below shows connected to the PLC. Then we click on the eye glasses which puts this VAT online with the PLC and also puts the VAT table into live monitoring mode. Next we go back to the main Simatic Manager and open Test VAT

In our test we are just going online with the PLC to observe a VAT table. Then save the configuration (remember this just saves it in the windows PC project only, be careful not to do any hardware configuration updates on this PLC ethernet module. We also, checked do not use router as it is not required since our tech support gateway is on the same subnet as our development PC that is running the Step 7 development software. We changed the IP address to match that of our technical support gateway, and the subnet mask must be the same as the technical support gateway subnet. Record the IP address and Router address if it is used before making changes. Click on the properties box as shown below:

We are going to temporarily change the IP address in the project only, and then restore it later after we finish this session. This opens the Properties box for this ethernet module. Then double click on the etherne module as shown below: Next open the Siemens project and find the Hardware configuration line as shown and by double clicking open the Hardware configuration screen. We entered the Field Device TCP Port number 102 which was found by clicking on, “ Click for a list of common TCP Ports” shown on the “Manage My Remote” screen, and we entered the hardware configured IP address of the PLC as 10.0.5.15 in the Field Device IP Address box.

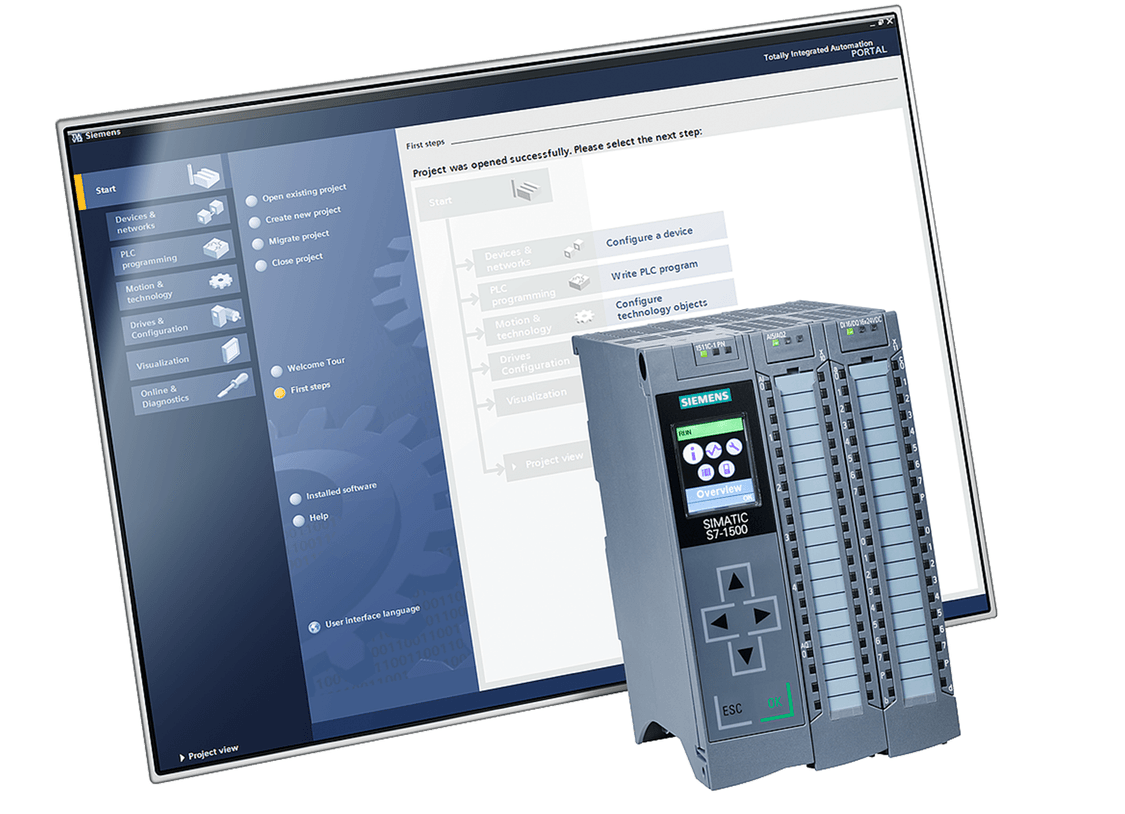

First login to your web page “Manage My Remote” on the website. The PLC resided on a private 10.0.5.x subnet using a CP 343-1 ethernet module. This is a remote connection session to a Siemens S7-300 PLC on Ethernet using Siemens Step 7 Simatic Software.

0 kommentar(er)

0 kommentar(er)